Over 33% of UK cars have damaged alloy wheels, costing owners around £68 per wheel—totalling £890 million in repairs annually, according to data from rimblades.com. Kerb damage alone causes over half of all wheel issues, yet most of this damage is entirely preventable.

Your alloy wheels face constant assault from kerbs, potholes, brake dust, road salt, and corrosive chemicals. Understanding how to protect them properly saves you money, maintains your vehicle’s appearance, and preserves resale value.

Contents

Why Alloy Wheels Are Vulnerable to Damage

Modern alloy wheels look fantastic but aren’t as indestructible as they appear. Understanding their vulnerabilities helps you take appropriate protective measures.

Material Properties and Weaknesses

Alloy wheels are typically manufactured from aluminium or magnesium alloys. These materials offer excellent strength-to-weight ratios, which improves handling and fuel economy, but they’re softer than steel and more susceptible to cosmetic damage.

The finish on alloy wheels—whether painted, powder-coated, diamond-cut, or polished—is relatively thin. Impact damage easily penetrates this protective layer, exposing the underlying metal to corrosion. Once the seal is broken, moisture and road salt can cause progressive deterioration.

Diamond-cut alloys are particularly vulnerable. The machined face has minimal protective coating, making them prone to corrosion if damaged. Repairing diamond-cut wheels is also more expensive because it requires specialist machinery to replicate the precise cutting.

UK-Specific Road Hazards

British roads present unique challenges for alloy wheels. In the 12 months before March 2023, Kwik Fit reported that 57% of British drivers hit a pothole at least once a week. This resulted in 2.7 million cars being forced off the road due to pothole damage, with annual repair costs reaching £1.7 billion.

Potholes cause impact damage that can crack alloys, bend rims, or damage the wheel’s internal structure—problems often invisible from external inspection. Even when cosmetic damage isn’t apparent, a pothole strike can cause slow air leaks or wheel balance issues.

Winter road salt accelerates corrosion dramatically. The salt and chemical treatments used on UK roads during winter months are highly corrosive to alloy wheels, particularly if existing damage has compromised the protective finish. Coastal areas face additional challenges from salt spray, which affects vehicles year-round.

Common Damage Types

Research from Mario’s Wheel Repair identifies five common alloy wheel damage types UK drivers encounter:

Kerb damage manifests as scrapes, gouges, or chunks missing from the wheel rim edge. This typically occurs during parking, tight turns, or misjudging clearances. It’s the most common form of alloy wheel damage, accounting for over 50% of all wheel repairs.

Corrosion damage appears as bubbling, pitting, or white powdery deposits on the wheel surface. It develops when the protective coating is compromised, allowing moisture and chemicals to attack the metal underneath. Left unchecked, corrosion spreads and can eventually cause structural weakness.

Impact damage from potholes or severe bumps can crack alloy wheels or cause bends in the rim. Cracks are serious safety issues requiring immediate replacement, whilst bent rims often cause vibrations at speed and may be repairable depending on severity.

Brake dust contamination isn’t damage per se, but if left to accumulate, it bonds to the wheel surface and becomes extremely difficult to remove. The metallic particles in brake dust are corrosive and can etch into the wheel finish over time.

Chemical damage from harsh wheel cleaners, particularly those containing strong acids or alkalis, can degrade protective coatings and discolour wheel finishes. This is entirely preventable with proper product selection.

Protective Coatings for Alloy Wheels

Modern protection technology offers several options for creating a barrier between your wheels and the elements.

Ceramic Wheel Coatings

Ceramic coatings designed specifically for wheels create a hard, chemically bonded layer that protects against contamination and makes cleaning dramatically easier. These products use similar technology to paint ceramic coatings but are formulated to withstand the extreme temperatures wheels experience during braking.

Gtechniq’s C5 Wheel Armour is engineered specifically for this purpose. It provides exceptional protection against brake dust, road grime, and chemical contamination. The coating’s heat resistance up to 300°C ensures it won’t degrade even during hard braking on performance vehicles.

The hydrophobic properties of ceramic wheel coatings mean brake dust and road grime struggle to bond to the wheel surface. Water beads and runs off, taking loose contamination with it. Regular washing becomes quick and simple—often just a pressure washer rinse is sufficient to restore the wheels to near-perfect condition.

Application requires thorough preparation. Wheels must be completely decontaminated, ideally with an iron remover to eliminate all brake dust particles. Any existing damage should be repaired before coating, as the ceramic layer will seal the current condition in place. Professional application typically costs £80-120 per set of four wheels, according to UK detailing pricing.

Traditional Wheel Sealants

Polymer-based wheel sealants offer a more affordable, DIY-friendly alternative to ceramic coatings. Products like Gtechniq W1 Alloy Wheel Soak provide excellent cleaning and temporary protection in a single application.

These sealants don’t bond as permanently as ceramic coatings, typically lasting 1-3 months depending on driving conditions and cleaning frequency. However, they’re quick to reapply and still provide meaningful protection against brake dust adherence and chemical contamination.

The advantage is accessibility—you can apply these products at home without special equipment or training. They’re ideal for maintaining wheels between professional ceramic coating applications or for drivers on tighter budgets.

Powder Coating and Refinishing

For wheels with existing damage or those requiring maximum durability, powder coating offers unmatched protection. The process involves stripping the wheel to bare metal, then applying electrostatically charged powder that’s cured in an oven to create an extremely hard, durable finish.

Powder coating is significantly more resistant to chips, scratches, and chemical damage than factory paint finishes. It’s an excellent option for refurbishing damaged wheels or customising wheel colour whilst adding protection.

The process costs approximately £60-100 per wheel in the UK, making it a £240-400 investment for a set of four. However, a properly powder-coated wheel can last the lifetime of the vehicle without requiring refinishing, making it cost-effective long-term protection.

The limitation is that once powder-coated, you’re committed to that colour unless you strip and recoat again. It’s not reversible like a ceramic coating that can be removed with polishing.

Physical Protection Methods

Protective coatings address chemical and contamination damage, but physical barriers are needed to prevent impact and kerb damage.

Alloy Wheel Rim Protectors

Rim protectors are resilient polyurethane or flexible plastic strips that fit into the groove between the tyre and wheel rim. They create a sacrificial barrier that absorbs impacts when you contact a kerb, protecting the alloy underneath.

AlloyGator wheel protectors are trusted by over 1 million drivers. These products are designed to provide essential damage prevention and are fixed to the rim of the wheel so that if contact is made, it’s with the rim protector rather than the alloy itself.

Installation is straightforward—most designs clip into place without adhesives, making them removable if you later decide they’re unnecessary or want to change colour. They’re available in numerous colours, allowing you to match your vehicle’s colour scheme or create a custom contrast look.

The protection is genuine. Rim protectors can prevent the vast majority of kerb damage from parking incidents and tight manoeuvres. However, they won’t protect against severe impacts or pothole damage—they’re designed for the scrapes and scuffs that occur during normal driving.

Cost is modest, typically £40-80 for a set of four wheels. When you consider that a single kerb damage repair costs £68 on average, they can pay for themselves by preventing just one incident.

Tyre Pressure and Sidewall Protection

Maintaining correct tyre pressures is one of the most overlooked aspects of wheel protection. Underinflated tyres reduce the cushioning effect between the wheel and road surface, making impact damage from potholes far more likely.

Check your tyre pressures monthly—not just before long journeys. Tyres naturally lose approximately 1-2 PSI per month through normal permeation, and temperature changes affect pressures significantly. A 10°C temperature drop can reduce tyre pressure by 1-2 PSI.

Consider running tyres at the higher end of manufacturer specifications if you regularly drive on poor road surfaces. The additional pressure provides more cushioning against impacts, though it may slightly affect ride comfort and grip in extreme conditions.

Choosing tyres with robust sidewalls also helps. Performance tyres with low profiles look fantastic but offer minimal protection against wheel damage from impacts. If you drive frequently on poor roads, consider slightly higher-profile tyres that provide more cushioning.

Cleaning Practices That Protect

How you clean your wheels significantly affects their long-term condition. Proper cleaning removes harmful contamination whilst avoiding damage from harsh chemicals or abrasive techniques.

Safe Wheel Cleaning Products

pH-neutral wheel cleaners are the safest choice for all wheel types. These products effectively remove dirt and light contamination without attacking protective coatings or the wheel finish itself. They’re suitable for regular maintenance washing every 1-2 weeks.

For heavier contamination, particularly baked-on brake dust, you need stronger solutions. Iron removers like Gtechniq W6 Iron and General Fallout Remover chemically dissolve metallic brake dust particles without requiring aggressive scrubbing. These products turn purple as they react with iron particles—a visual confirmation they’re working.

Avoid highly acidic wheel cleaners (pH below 4) unless absolutely necessary, and never leave them on wheels longer than recommended. Strong acids can etch aluminium, damage clear coats, and degrade protective coatings. If you must use acidic cleaners, rinse thoroughly and immediately neutralise with pH-neutral shampoo.

Similarly, avoid highly alkaline cleaners (pH above 10) on diamond-cut or polished wheels. These can cause oxidation and discolouration on exposed aluminium surfaces.

Proper Washing Technique

Wheels should be washed first, before the paintwork. This prevents contaminated run-off from landing on freshly washed paint. Use dedicated wheel brushes and separate wash mitts for wheels—never use the same tools on wheels and paint.

Start by rinsing wheels thoroughly with a pressure washer or strong hose spray to remove loose dirt. This prevents you from grinding abrasive particles into the wheel finish during washing.

Apply your chosen wheel cleaner and allow appropriate dwell time—typically 3-5 minutes for general cleaners, less for acid-based products. Agitate gently with soft-bristled brushes, paying attention to spoke recesses and the wheel barrel (inside face).

For wheel barrels and hard-to-reach areas, use dedicated long-reach brushes. These areas accumulate substantial brake dust and contamination that isn’t visible from the outside but contributes to corrosion if left uncleaned.

Rinse thoroughly, ensuring all cleaning product is removed. Residual chemicals can cause staining or damage if left to dry on the wheel surface.

Frequency and Seasonal Considerations

Wash wheels every 1-2 weeks as a baseline. More frequent cleaning is necessary during winter months when road salt and chemical treatments are prevalent. Salt accelerates corrosion dramatically, and removing it promptly prevents long-term damage.

After driving through particularly harsh conditions—heavy rain, coastal areas, gritted roads, or muddy terrain—clean your wheels as soon as practical. Don’t let contamination sit for days or weeks between regular washes.

Some drivers perform a quick maintenance clean mid-week, especially during winter. This needn’t be a full wash—simply spray with pH-neutral cleaner, agitate with a soft brush, and rinse. Five minutes per wheel prevents contamination from bonding and makes your weekly full wash easier.

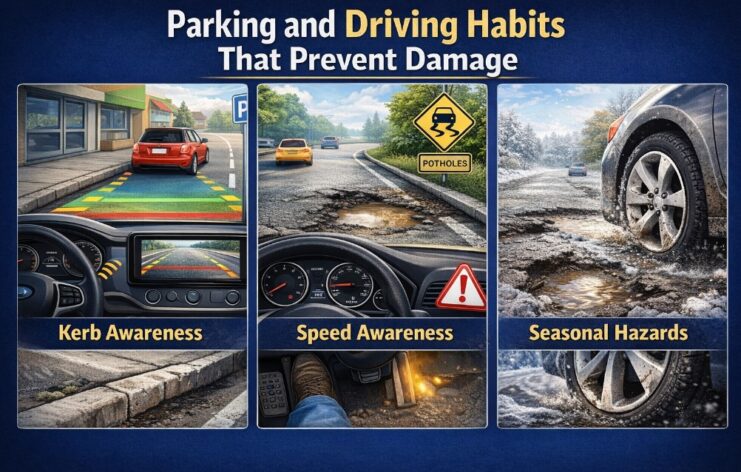

Parking and Driving Habits That Prevent Damage

Your everyday driving behaviour has more impact on wheel condition than any protective product.

Kerb Awareness and Parking Techniques

Kerb damage causes over half of all alloy wheel issues, yet it’s entirely preventable with awareness and technique adjustments. When parallel parking, leave slightly more clearance than feels necessary until you’re confident of your vehicle’s dimensions.

Modern parking sensors help, but they typically don’t detect kerbs effectively—they’re optimised for detecting other vehicles and vertical obstacles. Consider adding parking cameras to supplement sensors, particularly rear-facing cameras that clearly show wheel position relative to kerbs.

When parking, avoid turning the steering wheel whilst stationary or barely moving. This scrubs tyres across the kerb and increases the likelihood of catching the wheel rim. Instead, straighten up before your final positioning adjustments.

In tight parking spaces, it’s often safer to take an extra minute and reposition than to risk kerb contact rushing into a marginal space. The 30 seconds you save isn’t worth £68 per wheel in repair costs.

Speed Awareness for Road Hazards

Potholes are increasingly common on UK roads, but they’re often avoidable with attentive driving. Maintain appropriate speeds for conditions—excessive speed gives you less reaction time to spot and avoid road hazards.

When you can’t avoid a pothole, reducing speed significantly decreases impact force. Hitting a pothole at 20mph versus 40mph can be the difference between no damage and a cracked wheel. If you see a hazard ahead, brake before impact, then release the brakes just before contact. This allows the suspension to absorb the impact more effectively.

Avoid sudden swerves to dodge potholes. Verify it’s safe to change position before manoeuvring—hitting another vehicle is considerably worse than wheel damage.

Seasonal Considerations

Winter driving demands extra caution. Potholes fill with water, making their depth impossible to judge visually. Frozen ground makes road surfaces less forgiving, increasing impact severity. Drive conservatively and assume puddles may be hiding hazards.

After winter, inspect your wheels thoroughly. Look for cracks, bends, or new corrosion developing. Small issues caught early are cheaper and safer to address than damage that’s progressed to structural compromise.

Inspection and Maintenance Schedule

Regular inspections catch developing problems before they become serious damage or safety issues.

Monthly Visual Inspections

Once monthly, clean your wheels thoroughly and inspect them in good lighting. Look for:

- New scuffs, scratches, or gouges in the wheel rim

- Developing corrosion, particularly around damaged areas

- Cracks in the wheel spokes or rim (these are safety-critical—seek professional assessment immediately)

- Unusual wear patterns on tyres that might indicate wheel or suspension damage

- Loose or missing wheel weights

Pay particular attention to the inside wheel rim and barrel areas. These are less visible but accumulate contamination and can develop corrosion unnoticed.

Pressure Checks and Balance

Check tyre pressures monthly, ideally when tyres are cold (before driving or at least three hours after). Record the readings—if you notice one tyre consistently losing pressure, investigate for slow leaks that might indicate wheel damage.

If you experience vibrations at speed, particularly at motorway speeds, have your wheels checked for balance issues. Imbalance can result from lost wheel weights, but it can also indicate bent wheels from pothole impacts.

Balancing costs approximately £10-15 per wheel—a modest investment that prevents excessive tyre wear and ensures comfortable driving. Wheels should be rebalanced when fitting new tyres and whenever you notice vibrations.

Professional Assessment

Consider professional wheel inspection annually, particularly if you drive in challenging conditions or have experienced significant impacts. Professionals can detect cracks, structural weakness, or developing issues that aren’t visible to untrained eyes.

Mobile TPMS (Tyre Pressure Monitoring System) equipped vehicles provide continuous pressure monitoring. Pay attention to warnings—sudden pressure loss could indicate wheel or tyre damage requiring immediate attention.

Repair vs Replacement Decisions

When damage occurs despite preventive measures, you’ll face the repair or replacement decision.

When Repair Is Appropriate

Cosmetic damage—scuffs, scratches, and minor gouges—is typically repairable. Professional alloy wheel refurbishment can restore wheels to near-original condition for approximately £68 per wheel on average, according to UK repair cost data.

Surface corrosion is also repairable if caught before it causes structural issues. The wheel is stripped, corroded areas are treated, and protective coating is reapplied. This costs more than simple cosmetic repair but remains more economical than replacement.

Minor bends in wheel rims can sometimes be straightened, though this requires specialist equipment and expertise. Not all bends are safely repairable—it depends on severity and location. Always seek professional assessment rather than attempting DIY straightening.

When Replacement Is Necessary

Cracks anywhere in the wheel structure require immediate replacement. Cracked wheels can fail catastrophically at speed, causing loss of vehicle control and potentially serious accidents. There is no safe repair for cracked alloys.

Severe bends that affect structural integrity also necessitate replacement. A wheel that’s been bent beyond safe repair limits will never balance properly and presents ongoing safety risks.

If repair costs approach replacement costs, replacement usually makes more sense. You’ll have a pristine wheel with no history of damage, which matters for resale value.

Insurance Considerations

Alloy wheel insurance is available as additional cover from various providers. Policies often start around £50 annually, with car2cover Alloy Wheel Insurance providing up to 4 claims per year and 10 total, with up to £150 per claim.

Whether this represents value depends on your risk profile. If you regularly damage wheels or have expensive wheels (premium brands or large diameters), insurance can be worthwhile. For most drivers with average-priced alloys and decent parking skills, self-insuring is more economical long-term.

Frequently Asked Questions

What’s the most effective way to prevent kerb damage?

The most effective prevention is developing spatial awareness of your vehicle’s dimensions and leaving adequate clearance when parking. Parking cameras showing wheel position are invaluable. If you’re uncertain, take an extra minute to reposition rather than risk contact. Rim protectors provide excellent backup protection for occasional misjudgements, preventing damage in situations where you’d otherwise scrape the alloy.

Can I use regular car polish on alloy wheels?

It depends on the wheel finish. Painted or powder-coated wheels can generally accept car polish, though dedicated wheel polishes work better. Never use abrasive polishes on diamond-cut wheels—you’ll damage the machined surface. For polished aluminium wheels, use metal polish specifically designed for aluminium. When uncertain about your wheel type, consult your vehicle’s documentation or use products specifically labelled safe for all wheel finishes.

How often should alloy wheels be deep cleaned?

Perform deep cleaning quarterly as a minimum, more frequently if you drive in harsh conditions. Deep cleaning involves thorough decontamination with iron removers, cleaning wheel barrels and behind spokes, and removing all bonded contamination. This prevents long-term corrosion development and maintains any protective coatings you’ve applied. Between deep cleans, regular weekly washes with pH-neutral products maintain wheel condition.

Are ceramic coatings worth it for alloy wheels?

For most drivers, yes. Ceramic wheel coatings make maintenance dramatically easier, protect against chemical damage, and can last 2-5 years with proper care. The upfront cost of £80-120 for professional application is recovered through reduced cleaning time, reduced product usage, and prevention of deterioration that would require refurbishment. They’re particularly valuable if you drive a prestige vehicle, have expensive wheels, or simply value easy maintenance.

What should I do immediately after hitting a pothole?

Safely pull over when practical and inspect the wheel and tyre for visible damage—cracks, bulges, or severe scrapes. Check tyre pressure—significant air loss indicates possible damage. Drive cautiously to assess for vibrations or handling changes. If you notice issues, have the wheel professionally inspected before motorway driving. Even if everything seems fine, monitor tyre pressure over the following days for slow leaks indicating rim damage.

Protecting Your Investment

Alloy wheels represent significant value—replacements typically cost £150-500 per wheel depending on size and specification. Protecting them makes financial sense beyond aesthetic considerations.

The combination of protective coatings, careful driving habits, and proper maintenance prevents the vast majority of damage UK drivers encounter. Products like Gtechniq’s C5 Wheel Armour provide professional-grade chemical protection that dramatically reduces cleaning time whilst preventing corrosion. Combined with rim protectors for physical impact protection, your wheels can maintain showroom condition for years.

The investment in protection—whether ceramic coatings, rim protectors, or simply quality cleaning products—is modest compared to repair or replacement costs. More importantly, prevention is far less time-consuming than dealing with damaged wheels, particularly if that damage has progressed to require refurbishment or replacement.

Your wheels endure some of the harshest conditions any vehicle component faces. Protecting them appropriately ensures they continue looking excellent whilst maintaining structural integrity and safety throughout your ownership.