Selective Catalytic Reduction (SCR) has become the go-to technology for reducing nitrogen oxide (NOx) emissions in diesel engines. Whether you’re running a fleet of trucks or maintaining a single heavy-duty vehicle, SCR plays a big role in keeping your engine compliant with emissions regulations. But like any system, it’s not immune to issues — and when it fails, you feel it in both performance and repair bills.

Today, I’ll break down the most common problems drivers and mechanics encounter with SCR systems, along with practical ways to fix them before they turn into bigger headaches.

Contents

Key Points

- SCR problems often start small but can quickly lead to performance loss and downtime.

- DEF contamination, dosing malfunctions, and sensor failures are among the top culprits.

- Many issues can be prevented with regular inspections and correct DEF handling.

- Some repairs require professional service, while others can be handled with basic maintenance.

- Ignoring SCR problems risks costly fines and extended truck downtime.

The Basics: Why SCR Systems Fail

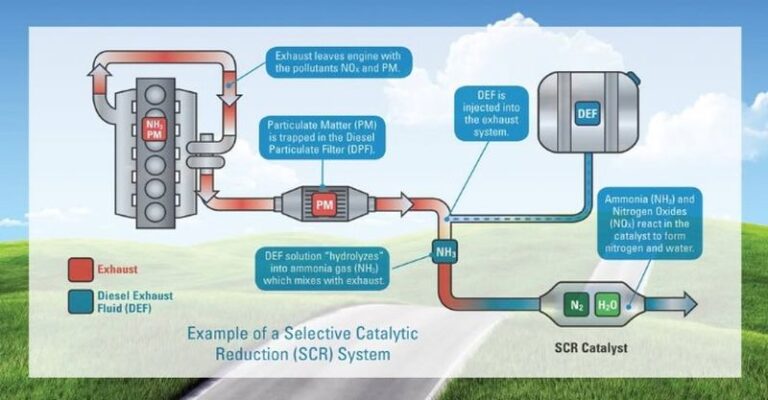

SCR systems are designed to inject Diesel Exhaust Fluid (DEF) into the exhaust stream, where it reacts with NOx gases and breaks them down into harmless nitrogen and water. It’s a simple concept, but in the real world, a combination of heat, vibration, road debris, and human error can create perfect conditions for failure.

Most problems trace back to:

- Improper DEF handling – Using contaminated fluid or storing it incorrectly.

- Component wear – Pumps, injectors, and sensors degrade over time.

- Software issues – Calibration errors and outdated firmware in the control module.

If you’ve ever seen the dreaded “SCR fault” light come on mid-route, you know the sinking feeling that follows. It’s not just about emissions — it can throttle your engine power and force you into limp mode.

Most Common Problems in Selective Catalytic Reduction

Over time, a handful of recurring problems tend to appear in SCR systems, and being able to spot them early can save both money and frustration.

1. DEF Contamination: The Silent System Killer

One of the most common and easily overlooked SCR problems is DEF contamination. Diesel Exhaust Fluid is extremely sensitive to impurities. Even a small amount of dirt, oil, or the wrong type of water can disrupt the chemical reaction needed for NOx reduction.

Contamination leads to:

- Clogged injectors.

- Crystallization in the dosing lines.

- Inaccurate DEF level readings.

I’ve seen fleet trucks sidelined for days because someone topped off DEF using an old fuel jug. It’s an avoidable mistake — but one that happens more often than you’d think.

2. Dosing Module Malfunctions and the Role of Professional Repair

The dosing module is the heart of the SCR system, responsible for delivering the right amount of DEF into the exhaust stream. When it fails, emissions skyrocket and your system may shut down to prevent damage.

Here’s the thing — dosing problems aren’t always obvious until the check engine light appears. You might notice reduced fuel efficiency, sluggish acceleration, or excessive DEF usage before the fault code even appears.

This is where having a trusted DEF repair service makes all the difference. Professionals can run diagnostics, check injection patterns, and replace faulty modules without unnecessary guesswork. For owner-operators, investing in skilled service early can save thousands in missed loads and penalties.

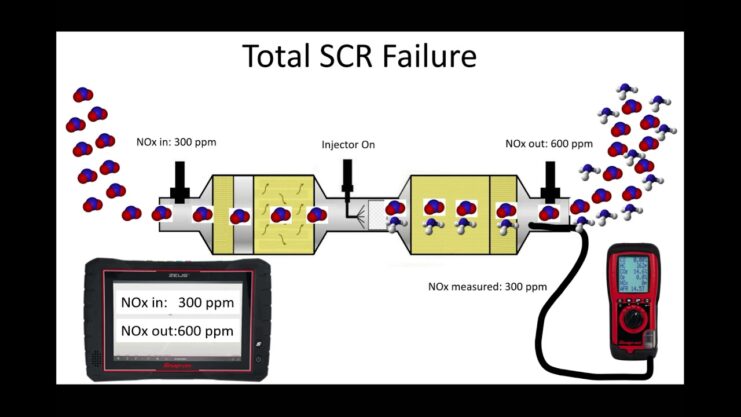

3. Sensor Failures: When Data Goes Wrong

SCR systems rely heavily on sensors — NOx sensors, temperature sensors, and DEF quality sensors — to calculate how much fluid to inject.

Common issues include:

- NOx sensor drift – Readings slowly become inaccurate, leading to poor dosing.

- DEF quality sensor faults – Mistakenly detecting contamination, triggering warnings.

- Temperature sensor failure – Misreporting exhaust temps and preventing proper reaction.

Replacing sensors isn’t cheap, but ignoring faulty ones often means the system will overcompensate, using more DEF than necessary or underperforming in emission reduction.

4. Crystallization in the DEF System

If DEF is exposed to air for too long or stored in fluctuating temperatures, it can crystallize. Those white deposits clog injectors, coat sensors, and choke lines.

What you can do:

- Flush the system regularly, especially in colder months.

- Use DEF within one year of purchase — it has a shelf life.

- Keep tanks sealed tightly to prevent air exposure.

Crystallization is one of those problems that sneaks up on you, but catching it early can turn a costly system overhaul into a quick cleaning job.

5. Clogged DEF Lines and Filters

Much like a fuel system, your DEF system has filters to prevent debris from entering the dosing module. Over time, these filters can become clogged, restricting flow and causing system faults.

Preventive tip: replace DEF filters according to the manufacturer’s schedule — and don’t stretch it “just one more trip.” DEF filters are inexpensive compared to the downtime of a failed system.

6. Electrical and Wiring Issues

SCR systems are heavily dependent on electronics, and trucks live in a world of vibration, moisture, and road salt — all enemies of clean wiring. Loose connections, corroded plugs, or damaged harnesses can trigger false error codes or complete shutdowns.

Good practice is to include wiring inspections in your regular service schedule. Many “mystery” SCR problems I’ve seen boiled down to nothing more than a loose ground or frayed wire.

7. Software and Calibration Problems

As emissions regulations evolve, manufacturers release software updates for SCR control units. Skipping these updates can mean your system is running outdated calibrations, leading to incorrect dosing and unnecessary system warnings.

If your truck is in for service, ask your mechanic to check for control module updates. It’s a quick step that can prevent headaches down the road.

How to Prevent Most SCR Failures

Prevention is the easiest way to avoid costly SCR repairs. With a few consistent habits, the system can run for years without major faults.

- Store DEF correctly – Keep it in sealed containers, away from heat and direct sunlight. High temperatures reduce shelf life, and freezing can damage its composition.

- Use clean, dedicated tools – Even a small trace of fuel or oil in funnels or jugs can contaminate DEF. Reserve equipment specifically for DEF handling.

- Stick to service intervals – Change DEF filters, inspect sensors, and check dosing lines when scheduled. Neglect here is one of the fastest ways to cause injector clogs.

- Train drivers – Make sure operators know how to fill DEF tanks properly, spot early warning lights, and report abnormal fluid usage.

- Include SCR in regular inspections – A quick look for crystallization, loose wires, or damaged fittings during routine maintenance can catch problems before they escalate.

These small steps take little time but greatly reduce the risk of unexpected downtime — and that’s what keeps trucks working instead of sitting in the shop.

When to Handle It Yourself — and When Not To

Some SCR issues are simple enough for in-house maintenance: replacing filters, cleaning crystallized lines, or topping off DEF correctly.

But if you’re dealing with:

- Repeated dosing faults.

- Multiple sensor errors.

- System derate warnings.

…it’s worth getting a certified DEF repair service involved. They have the diagnostic tools to pinpoint issues without unnecessary parts swapping.

Final Thoughts

SCR technology keeps diesel engines compliant, but it demands respect in handling and maintenance. Most problems boil down to contamination, neglected service schedules, or overlooked system warnings. Address issues early, and you’ll avoid the costly cycle of breakdowns, fines, and lost work.